Features

1. The cylinder is in accordance with the ISO15552.

2. The piston seal adopts two Y type one-way seals with compensation function, long service life and low starting pressure.

3. The cylinder cushion adjustment is smooth and the cushioning distance is long.

4. The cylinder bearings and wear rings have long distances and better lateral load performance.

5. The front and rear cover and piston adopt high pressure casting technology, with beautiful appearance and stronger strength.

![]()

Internal Structure

Parts

|

Number |

Name |

Number |

Name |

|

1 |

Hexagon nut |

10 |

Tie Rod |

|

2 |

Piston rod |

11 |

Barrel |

|

3 |

Shaft seal |

12 |

O ring |

|

4 |

DU Bearing |

13 |

Piston |

|

5 |

Cover screw |

14 |

Anti-friction ring |

|

6 |

Front cover |

15 |

Piston seal |

|

7 |

Cushion adjust screw |

16 |

O ring |

|

8 |

0 ring |

17 |

Back cover |

|

9 |

Cushion seal |

|

![]()

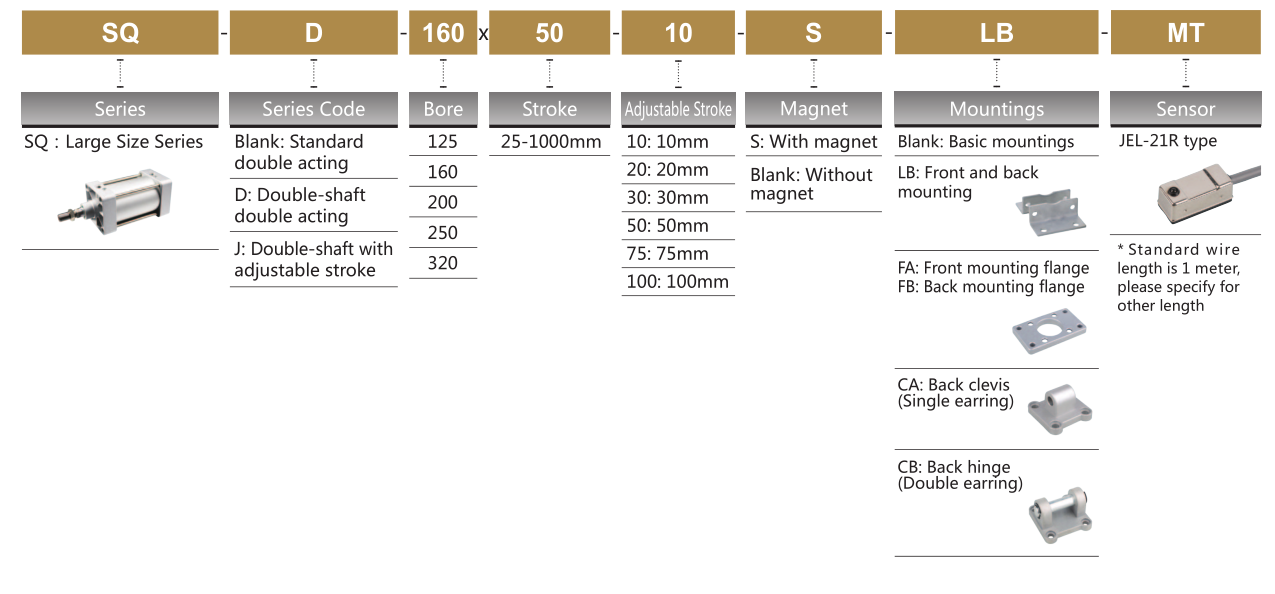

Ordering Code

![]()

Specification

|

Bore (mm) |

125 |

160 |

200 |

250 |

320 |

|

Operation |

Double Acting |

||||

|

Working Medium |

Air |

||||

|

Mounting |

Basic FA FB CA CB LB |

||||

|

Operating Pressure Range |

0.1~1MPa |

||||

|

Proof Pressure |

1.5MPa |

||||

|

Operating Temperature Range |

-20~70℃ |

||||

|

Operating Speed Range |

30-500mm/s

|

||||

|

Cushion |

Adjustable Cushion |

||||

|

Adjustable Cushion Stroke |

40mm |

50mm |

|||

|

Port Size |

G1/2" |

G3/4" |

G1" |

||

Overall Dimension

Dimension

|

Bore/Symbol |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

|

125 |

279 |

119 |

160 |

60 |

74 |

45 |

46 |

54 |

41 |

13.5 |

M27×2 |

|

160 |

332 |

152 |

180 |

65 |

94 |

58 |

50 |

72 |

55 |

18 |

M36×2 |

|

200 |

347 |

167 |

180 |

75 |

100 |

67 |

50 |

72 |

55 |

18 |

M36×2 |

|

250 |

389 |

189 |

200 |

90 |

114 |

75 |

60 |

84 |

65 |

21 |

M42×2 |

|

320 |

436 |

216 |

220 |

110 |

126 |

90 |

65 |

96 |

75 |

24 |

M48×2 |

Overall Dimension

Dimension

|

Bore/Symbol |

L |

N |

O |

P |

Q |

R |

S |

T |

V |

W |

X |

Y |

|

125 |

M12 |

23 |

G1/2 |

14 |

12 |

14 |

140 |

110 |

32 |

27 |

4 |

60 |

|

160 |

M16 |

25 |

G3/4 |

15 |

12 |

20 |

178 |

140 |

40 |

36 |

6 |

65 |

|

200 |

M16 |

25 |

G3/4 |

15 |

12 |

20 |

220 |

175 |

40 |

36 |

5 |

75 |

|

250 |

M20 |

30 |

G1 |

20 |

10 |

25 |

270 |

220 |

50 |

45 |

8 |

90 |

|

320 |

M24 |

31 |

G1 |

35 |

15 |

35 |

350 |

270 |

63 |

55 |

10 |

110 |

* 1. Cylider with or without magnet is the same size. 2. The no marked size is same with SQ standard.