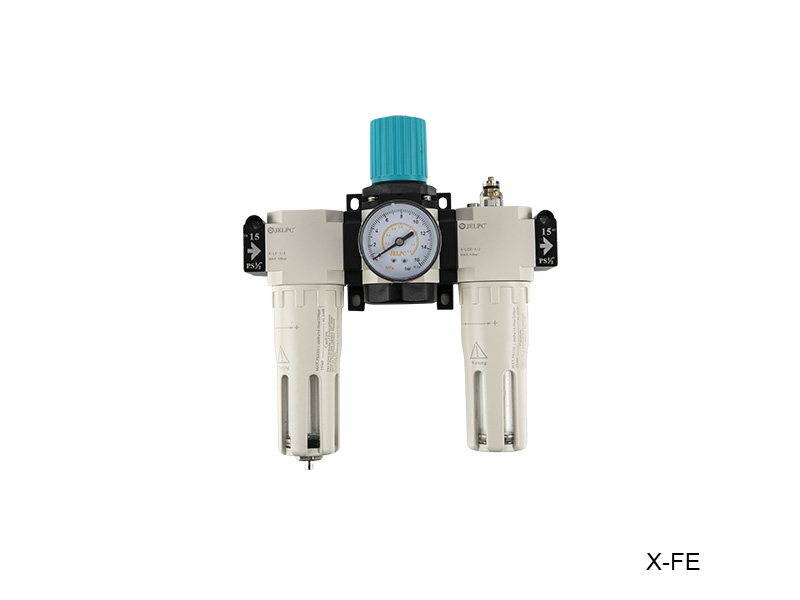

Filter regulator lubricators (FRLs) are an integral part of compressed air machines. They help keep air flowing and maintain downstream air pressure, as well as lubricate moving parts to reduce friction and improve efficiency. They can be purchased individually or as a package. They can be used in conjunction with filters, air regulators, and hose fittings.

Filters clean the air by separating it from liquids and solids, thereby removing impurities. Air line filters are often the first device the air makes contact with, so they are a vital component of air tools. Filters can be categorized according to the type of fluid they remove, including oil, liquid/vapour, and general-purpose filters. Pressure regulators are also an integral part of air tools, and regulate the output pressure in air bearings and cylinders.

The regulator should be able to accommodate different airflow rates, depending on the flow rate of the air. The regulators usually have adjustable knobs for adjustment. Some manufacturers also publish the minimum flow rate for their venturi. Filter regulators come in a variety of body and connection port sizes. A larger regulator will provide greater setting sensitivity, while a smaller regulator will have less droop.

Filter regulator lubricators use oil to lubricate the internal parts of a compressor. If oil is not lubricated, it may form a film and become sticky. This film will eventually cause varnish and sludge. Airlines lubricators use a metering system to meter oil from a reservoir into a moving airstream. This allows the air to draw the oil and break it up into a mist. The oil then travels downstream.

No 1.Xingjia Road, Pneumatic industrial park, Xikou,Ningbo, Zhejiang Zip code 315502

+86-574-88869818

+86-574-88869826

+86-574-88869817

+86-574-88869816

+86-574-88869833

royshan@jelpc.com

Copyright Ningbo Jiaerling Pneumatic Machinery Co.,Ltd.. All Rights Reserved.

China Proportional Valves Manufacturers